In the world of vehicle protection and surface preservation, the buzzwords “ceramic” and “graphene” coatings have become increasingly common. For car enthusiasts, professional detailers, and even DIYers, understanding these coatings and their applications can be the difference between a stunning finish and a lackluster surface. These advanced coatings offer a wide range of benefits, from gloss enhancement to extreme surface protection.

But why ceramic and graphene coatings? Both have emerged as leading technologies in the automotive world for their durability, protective qualities, and ease of maintenance. In this guide, we’ll dive deep into everything you need to know to master the application of both ceramic and graphene coatings, giving your vehicle the ultimate defense against the elements.

What Are Ceramic and Graphene Coatings?

Let’s start with a clear understanding of both types of coatings.

Ceramic coatings are liquid polymers that bond with a surface at the molecular level, creating a durable, semi-permanent layer of protection. They contain silicon dioxide (SiO2) and are primarily known for their hydrophobic qualities, which makes water bead off surfaces easily. A ceramic coating provides a protective layer that guards against UV rays, road salt, bird droppings, and minor scratches.

Graphene coatings, on the other hand, are relatively new to the scene. Derived from graphene oxide, they offer many of the same benefits as ceramic coatings but with added advantages. Graphene is a single layer of carbon atoms arranged in a honeycomb lattice, known for its exceptional strength, flexibility, and conductivity. When used as a coating, graphene provides an ultra-slick surface, superior anti-corrosion properties, and even better heat dissipation.

Benefits of Ceramic Coating

The popularity of ceramic coatings has skyrocketed for a reason. Here are some top benefits:

- Enhanced Protection: Ceramic coatings shield surfaces from environmental contaminants, such as acid rain, salt, and road grime.

- Aesthetic Appeal: A ceramic coating enhances the gloss and color depth of the vehicle, leaving a mirror-like finish.

- Hydrophobic Properties: Water beads and slides off the surface, making it easier to clean.

- UV Protection: Prevents paint from oxidizing and fading due to sun exposure.

Advantages of Graphene Coating

Graphene coatings offer additional benefits, surpassing even ceramic coatings in some areas:

- Superior Protection: Graphene is incredibly strong and provides even more resistance to scratches and environmental contaminants.

- Anti-Corrosion and Anti-Water Spotting: Due to its superior conductivity and heat dissipation, graphene prevents water spots from baking onto the surface.

- Anti-Static Properties: Graphene reduces dust and debris buildup on the vehicle, keeping it cleaner for longer.

- Hydrophobic Qualities: Like ceramic, graphene is highly hydrophobic, but with added slickness.

Comparing Ceramic vs. Graphene Coatings

When choosing between ceramic and graphene coatings, several factors come into play.

- Durability: Graphene coatings typically last longer than ceramic, sometimes up to 5 years or more, depending on the product and care.

- Cost: Graphene coatings are generally more expensive but offer better longevity and protection.

- Application: Both coatings require a meticulous process for application, but graphene’s ability to self-level can make it slightly easier for beginners.

Surface Preparation: The Key to Long-lasting Coatings

Before applying any coating, prepping the surface is crucial. Here’s why:

- A clean surface ensures proper bonding between the coating and the paint.

- Step 1: Wash the surface thoroughly, removing dirt and contaminants.

- Step 2: Use a clay bar to remove embedded particles.

- Step 3: Polish the surface to eliminate any scratches or imperfections.

Surface preparation ensures a flawless finish and maximizes the coating’s longevity.

Step-by-Step Application of Ceramic Coatings

To apply ceramic coating correctly, follow this guide:

- Clean and Dry: Make sure the surface is completely clean and free of moisture.

- Apply the Coating: Use an applicator pad to apply the ceramic coating in small sections, typically in a crosshatch pattern.

- Buff the Surface: After a few minutes (depending on the product), use a microfiber towel to buff the coating.

- Allow Curing Time: Give the coating time to bond and cure—usually 24 to 48 hours.

Step-by-Step Application of Graphene Coatings

For graphene coatings, the process is quite similar:

- Surface Prep: As with ceramic coatings, surface preparation is essential.

- Application: Use an applicator to apply the graphene coating evenly across the surface.

- Self-Leveling: Unlike ceramic coatings, graphene has self-leveling properties, meaning you can achieve a smooth finish with less effort.

- Buff and Cure: Buff the surface gently and allow it to cure for at least 24 hours.

Curing and Maintenance of Ceramic Coating

After applying ceramic coating, you must allow it to cure in a controlled environment, ideally free from moisture and contaminants. Avoid washing the vehicle for at least a week after application.

Maintenance involves regular washing with a pH-neutral soap and avoiding harsh chemicals that can break down the coating.

Curing and Maintenance of Graphene Coating

Graphene coatings require a similar curing process. After application, avoid direct sunlight and moisture. Graphene’s unique structure means less frequent maintenance, but regular gentle washes will help maintain its effectiveness over the years.

Common Mistakes in Coating Applications

Applying coatings isn’t foolproof. Avoid these common pitfalls:

- Skipping Surface Prep: A dirty or imperfect surface can cause the coating to fail.

- Over-Application: Using too much product can result in streaking or a hazy finish.

- Applying in the Wrong Environment: High humidity or direct sunlight can interfere with the curing process.

Choosing the Right Coating for Your Needs

The decision between ceramic and graphene coatings depends on factors like your budget, how often you drive, and the environmental conditions. For extreme protection, graphene might be the better option, but ceramic coatings are still an excellent, cost-effective choice.

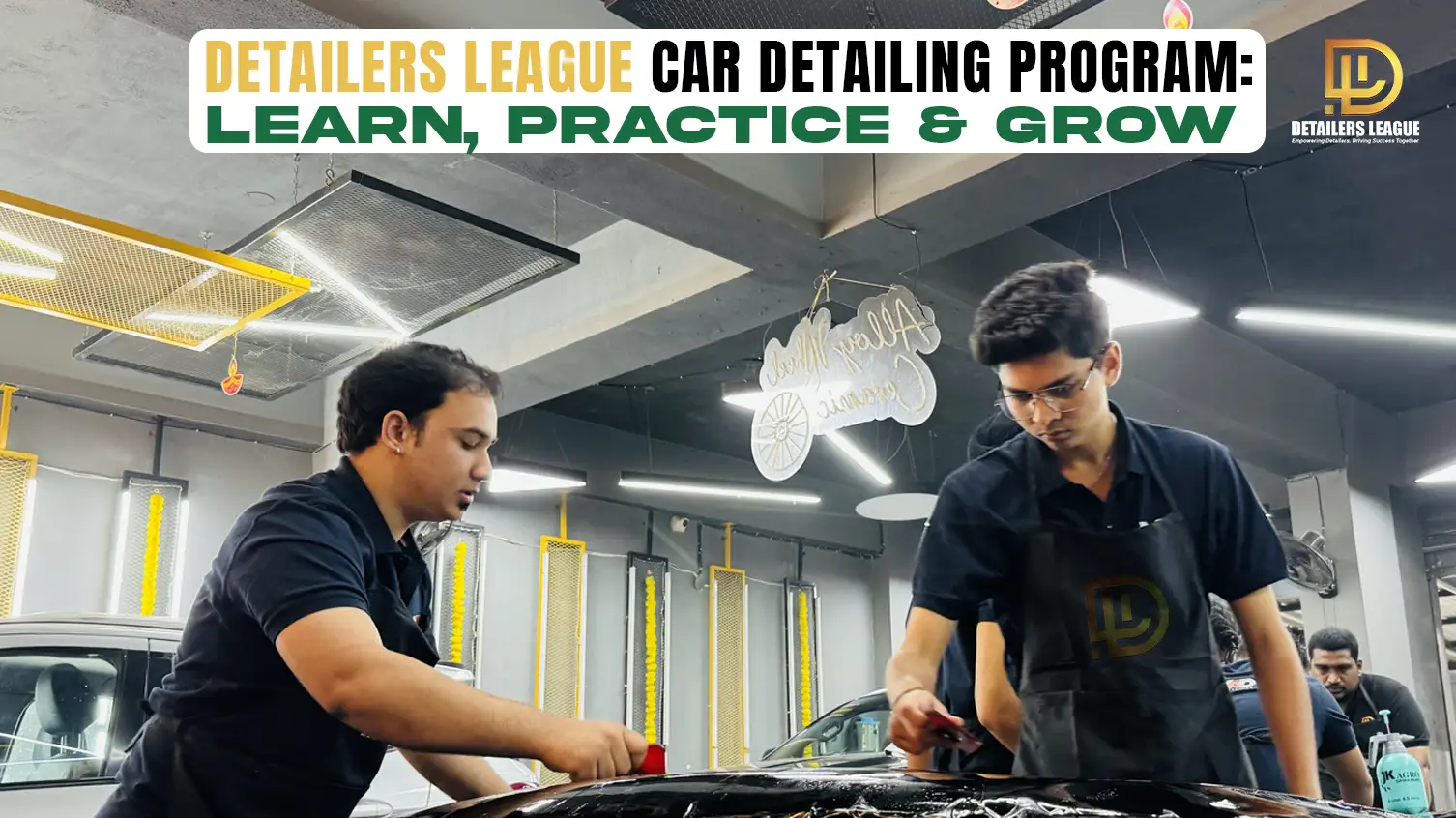

Professional Application vs. DIY: What to Consider

While DIY applications are possible, professional detailers offer precision and expertise that can be hard to match. Professionals use specialized tools and have experience in handling different coatings. However, DIY can save costs, as long as you’re willing to invest the time and care required for a proper application.

How to Remove Ceramic and Graphene Coatings

Over time, you may need to remove or replace an old coating. This can be done using polishers and specialized products designed to break down the coating. Always ensure proper safety precautions and techniques to avoid damaging the surface underneath.

Future of Surface Coating Technologies

As surface coatings evolve, new innovations are emerging. We can expect coatings with even better durability, faster application times, and eco-friendly options. Ceramic and graphene technologies continue to push the boundaries of what’s possible, ensuring that your vehicle stays protected and looking its best.

Conclusion

Mastering the art of ceramic and graphene coating application can be a game-changer for anyone who cares about surface protection. Whether you’re looking to boost the gloss and longevity of your vehicle or seeking to protect it from harsh elements, both ceramic and graphene coatings provide excellent options. With proper preparation, application, and maintenance, you can ensure your vehicle or surface remains pristine for years to come.